Technical information

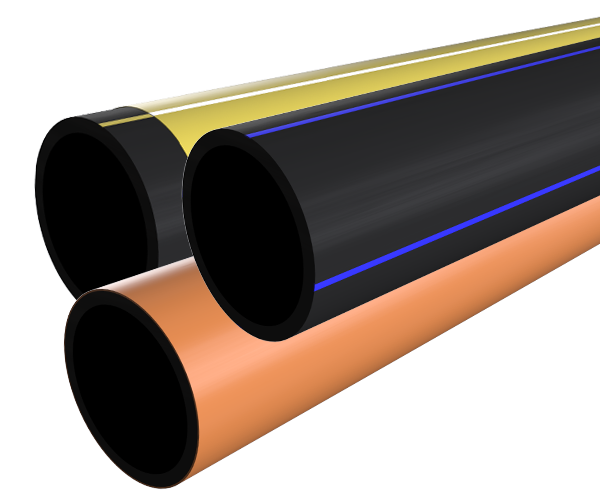

Pipe types

Below is a brief description of the pressure and non-pressure pipe types produced by HAKA Plast and their field of application.

Type 1

Type 1 or compact is a pressure or non-pressure pipe made of PE80, PE100, PE100-RC or PEHD REG raw materials.

Type 1 pipe is single-layer, to which only the marking is added after extrusion. Type 1 pipes are mainly suitable for installation in the open trench method, except for PE100-RC, which can also be installed in trenchless methods. Type 1 pressure pipe can be connected by butt and electrofusion welding.

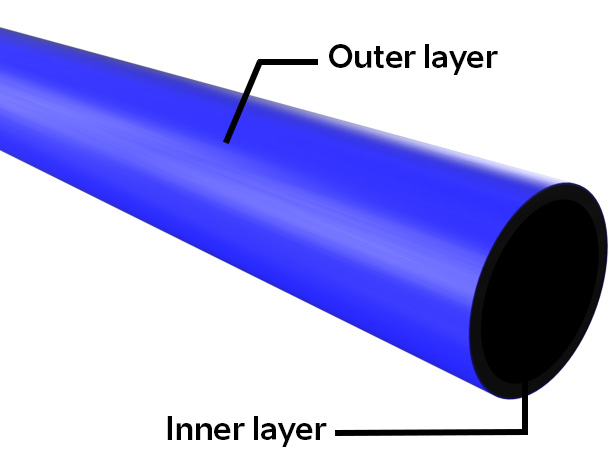

Type 2

Type 2 or co-extruded, is a two-layer pressure or non-pressure pipe produced by extrusion from two raw materials.

During extrusion, a second layer of raw material with the same or with similar physical properties is added to the first layer and both raw materials are merged together, but according to EN12201-2-2011 + A1-2013 it is still considered to be two layers. The thickness of the layers of a type 2 pipe is not specified in the mentioned standard, it is chosen by the manufacturer. The second or outer layer is often thinner and of a different color than the first or inner layer. The color of the outer layer indicates the use of the pressure or non-pressure pipe. For example, blue indicates a water pressure pipe and brown indicates a sewer pressure pipe. Type 2 non-pressure pipe is, for example a cable protection pipe. Unlike a pressure pipe with a PP coating (type 3), it is not possible to separate the layers of type 2 pressure or non-pressurized pipe. Type 2 pressure pipes are well suited for trenchless installation methods (no dig) where there is a risk of damaging the pressure pipe. If PE100-RC raw material is used, the type 2 pipe can also be installed in an open trench directly at the bottom of the trench without a gravel pad. If scratches or damage are visible, it must be made sure that the damage must not be deeper than 10% of the nominal wall thickness of the pipe (applies to pressure pipe). Type 2 pressure pipe can be connected by butt and electric welding.

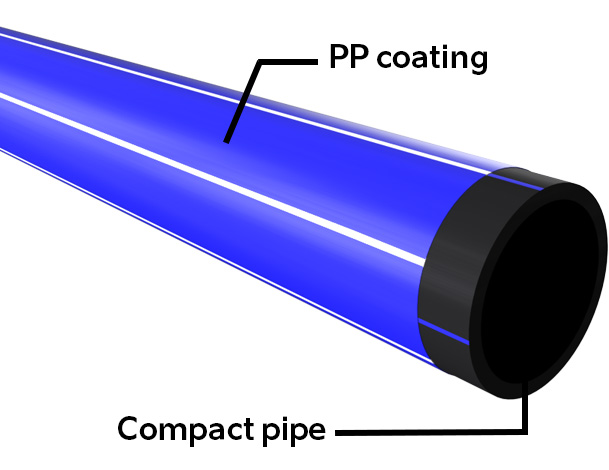

Type 3

Type 3 is a type 1 pressure pipe made of PE100-RC raw material, to which an outer layer of polypropylene (PP) has been added by extrusion to protect the inner pressure pipe in more difficult installation conditions.

Unlike a type 2 pipe, the type 3 layers do not melt together but where the PP layer adheres to the PE pipe because PP layer is added in later stage of extrusion. Type 3 pressure pipes are particularly well suited for trenchless installation methods (no dig), such as directional drilling, where there is a high risk that the pressure pipe may be damaged during installation. The outer PP layer of the HAKA Plast type 3 pressure pipe is peelable to allow the PE electrically welded sleeve or fitting to merge directly with the PE pressure pipe. The peeling layer is an additional advantage as it keeps the PE surface clean and fit for the electrofusion weld. Type 3 pressure pipe can also be butt welded by removing the outer PP coating.

© HAKA Plast | Tööstuse 35, 45201, Kadrina, Estonia | hakaplast[at]hakaplast.ee